SMC Resin: An Innovative and Safe Material for Your Next Project

Are you embarking on a new project and need a both material safe and innovative? Consider Fangxin SMC Resin, the perfect solution for a wide range of applications. This material has numerous advantages, is easy to use, and offers exceptional quality.

SMC resin is a composite material that offers numerous advantages, including its strength, durability, and versatility. SMC stands for Sheet Molding Compound, which means that it is a fibrous molded material into flat sheets. Once in sheet form, SMC Fangxin fiberglass mat resin can be shaped into any desired shape, making it perfect for a wide range of applications.

One of the most innovative aspects of SMC resin is its ability to be molded into complex shapes. This is due to its low viscosity, which means that the material flows easily and can be molded into complex shapes without the need for additional reinforcement materials. This makes Fangxin fiberglass resin an ideal material for applications where complex shapes are required, such as automotive parts, electrical enclosures, and industrial components.

SMC resin is also a safe material to use. It is non-toxic and non-corrosive, making it a safe choice for use in a wide range of applications. Additionally, Fangxin smc fiberglass resin is resistant to fire, chemicals, and moisture, making it a reliable choice for harsh environments.

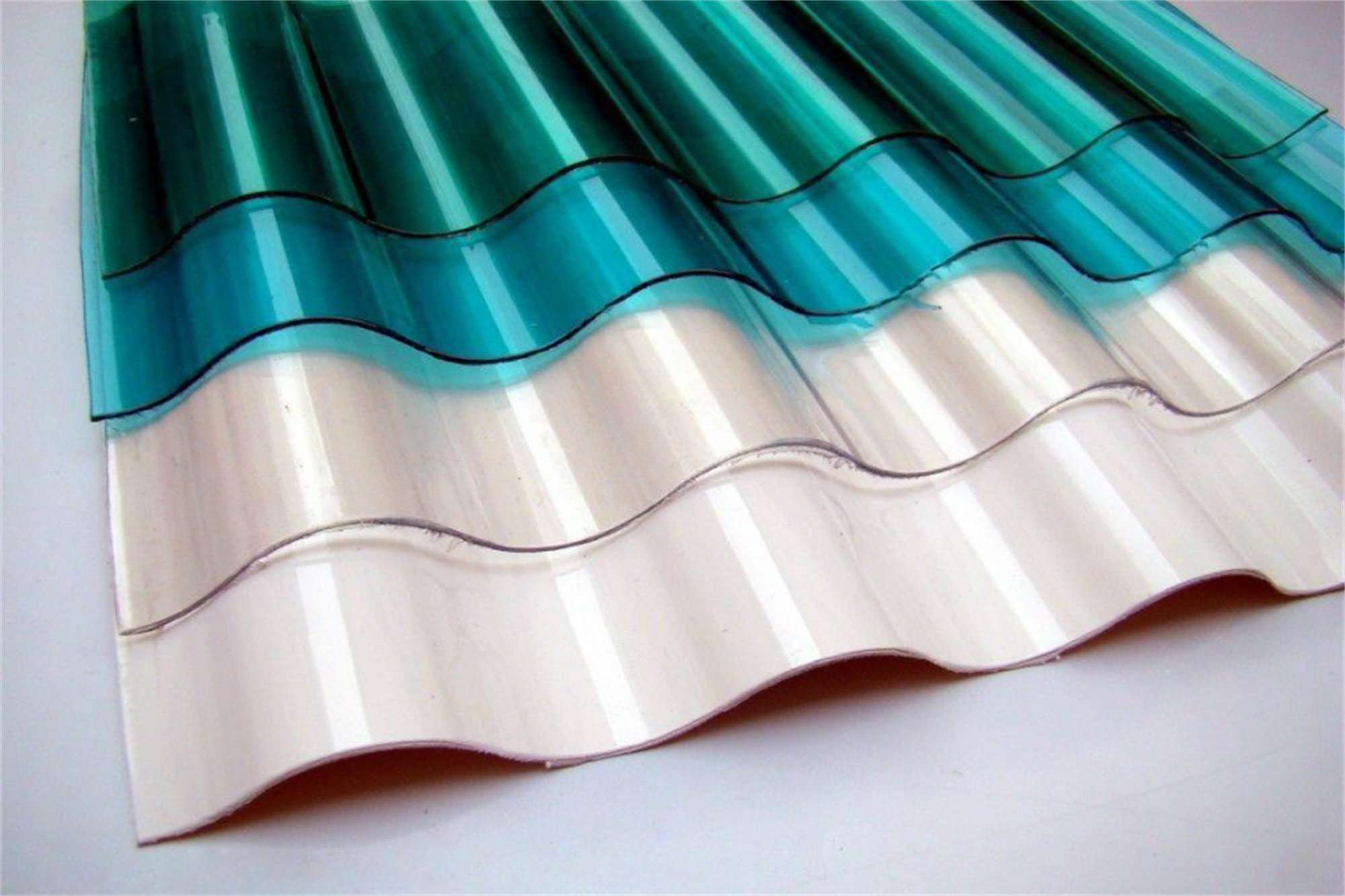

SMC resin is a versatile material that can be used in a wide range of applications. It is commonly used for automotive parts, such as hoods, fenders, and doors. It is also used in the construction industry for products such as roofing panels, electrical enclosures, and water tanks. Furthermore, SMC Fangxin resin and acrylic can even be used for recreational products such as kayaks and sailboats.

For more than 30 years, we've been focusing on research, development, production and sales unsaturated and uncolored resins, vinyl ester resins, alkyd and acrylic resins, waterborne resins, colored, color pastes other products, with almost 1,000.Fangxin been focused on research and development for over 30 years, as well as production and sales, of unsaturated epoxies esters alkyd acetate resins water-based resins, color SMC Resin as well as color pastes and other products. We have more a thousand products.

Company is able, with an experienced research development staff and an up-to-date R and D facility, to provide customers with a single-source shop for customers, including product customization. Additionally, have over 100 industry-specific certifications as well as national SMC Resin.Our team consists of highly skilled technical R and D group. Our team has a modern R and D center. Fangxin already earned dozens of patents, more than 100 industry-specific certifications, and national awards certification. Additionally, we've participated in the creation of various industry standards for resin. We are very confident that we can provide our customers one-stop SMC Resin services.

The company founded in 1992. It has three production facilities of a large scale that include over 100 resin manufacturing lines, an annual production capacity of 800,000 tons and fixed assets are worth more than 800 million Yuan. The total area covers 250,000 square meters.The company was established 1992 and has an initial capitalization of 350 million yuan, and fixed assets of more 800 million yuan. The company covers an area 250,000 square meters, and it has three huge production bases. It also more than 100 resin lines. The annual SMC Resin capacity is around 800,000 tones.

Our dedication lies in enhancing quality and diversity of our resin products, satisfying the various requirements of our clientele, and providing solutions that are tailored to the needs of our customers. We offer variety of options to our clients including SMC Resin on product as well as sample delivery and tracking, product testing and documentation for land and sea transportation.Many of our satisfied customers those in Mexico, Kenya, Tanzania, the United Arab Emirates, Russia as well as other regions.We're determined to improve the quality and diversity of resin products, addressing diverse SMC Resin of clients, and providing them with a variety of customized solutions. We assist customers with product consultation samples, delivery of samples, order tracking, testing of products along with land and sea transportation document processing and other related services. We have established long-term relationship with clients all over the globe, including Russia, UAE Kenya, Tanzania Mexico and many more.

SMC resin is easy to use and requires only a few basic tools. To use SMC resin, the material is first mixed with a catalyst to make it harden. Once mixed, the material can be molded into the desired shape using standard tools such as a roller or a press. The SMC Fangxin heat cured resin can then be cured under high heat and pressure to create a durable finished product.

SMC resin is readily available from a variety of suppliers, making it easy to find the material needed for your project. Additionally, suppliers of SMC Fangxin fiberglass sheets and resin typically offer technical support and training to ensure that you can use the material effectively for your specific application.

SMC resin offers exceptional quality, making it a reliable material for a wide range of applications. The material is resistant to a variety of environmental factors, including heat, moisture, and chemicals. Additionally, SMC Fangxin Frp Sheet Resin is lightweight but strong, making it an ideal material for projects where weight is a concern.

Copyright © Nantong Fangxin Chemical Co., Ltd. All Rights Reserved | Privacy Policy | Blog