Nhựa polyester orthophthalic là một loại nhựa cụ thể được sử dụng rộng rãi trong ngành công nghiệp composite. Nó có thể được sử dụng theo nhiều cách khác nhau. Nhựa polyester orthophthalic; hãy cùng tìm hiểu lý do tại sao nó lại quan trọng như vậy!

Dạng lỏng chất keo polyester orthophthalic là vật liệu cơ bản có thể được tùy chỉnh với các chất phụ gia khác nhau để tạo ra các vật liệu composite hiệu suất cao, nhẹ cân. Loại nhựa này thường được sử dụng để sản xuất các sản phẩm như thuyền sợi thủy tinh, phụ tùng ô tô và thậm chí cả vật liệu xây dựng.

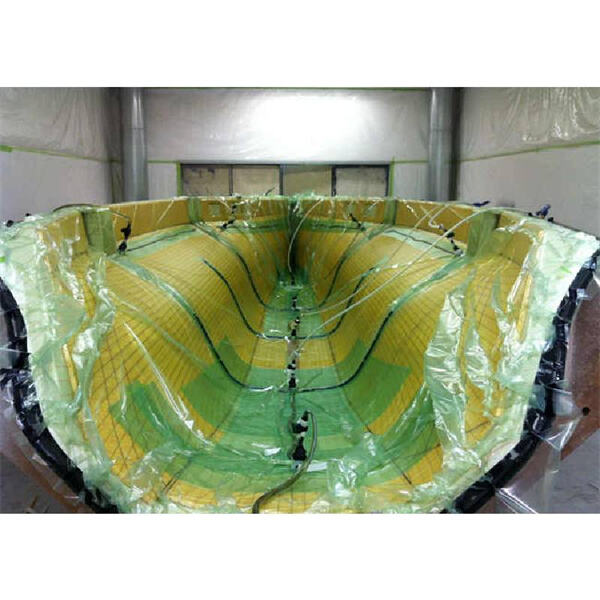

Một trong những điều tuyệt vời về nhựa polyester orthophthalic là nó rất dễ sử dụng. Nó có thể được đổ vào khuôn để cứng lại thành một sản phẩm mạnh mẽ và bền bỉ. Loại nhựa này bám dính tốt vào các vật liệu khác, điều này rất hữu ích cho quá trình được gọi là dán lớp. Dán lớp: quá trình xếp các lớp vật liệu lên nhau để tạo ra một sản phẩm mạnh mẽ hơn, bền hơn.

Quá trình đông cứng này sẽ là của keo polyester orthophthalic kết hợp với các vật liệu khác. Thời gian đông cứng là khi keo đông lại và trở nên rắn chắc. Chúng tôi tin rằng đây là một quy trình then chốt để tạo ra các sản phẩm vững chắc. Hiểu cách thức hoạt động của quá trình đông cứng giúp các nhà sản xuất phát triển các sản phẩm chất lượng cao có khả năng chịu đựng thử thách của thời gian.

Keo polyester orthophthalic được sử dụng trong nhiều ngành công nghiệp, bao gồm xây dựng và hàng hải. Trong xây dựng, nó được dùng để tạo ra các sản phẩm như tấm lợp mái, ống dẫn nước và thậm chí cả hồ bơi. Nó cũng được sử dụng trong việc xây dựng tàu thuyền, thân tàu và trong ngành công nghiệp hàng hải. Vì vậy, nó rất mạnh mẽ, nhẹ và có khả năng kháng nước và hóa chất, loại keo này rất phù hợp cho các ngành này.

Mặc dù nhựa polyester orthophthalic là một vật liệu tốt, tất nhiên có nhiều loại nhựa khác cũng có thể được sử dụng trong việc tạo composite. Nhựa isophthalic và vinyl ester là hai loại phổ biến. Hơn nữa, nhựa isophthalic rất bền và ít bảo trì, tăng khả năng kháng hóa chất, rất phù hợp cho môi trường khắc nghiệt. Nhựa vinyl ester cũng mạnh mẽ và kháng hóa chất nhưng linh hoạt hơn so với nhựa isophthalic. Việc sử dụng và lợi thế của mỗi loại nhựa là khác nhau.

Bản quyền © Công ty TNHH Hóa chất Fangxin Nantong. Tất cả các quyền được bảo lưu | Chính sách bảo mật|Blog