Acrylic acid resin is a pretty cool subject and is used for multiple applications. It's a type of moldable plastic that comes in many bright colors. Fangxin acrylic resin is engaged in the manufacture of useful acrylic acid resin products. So lets look closer into this wonderful material and why is it the best.

Acrylic acid resin contains special features which use it a perfect material for several merchandise. For one thing it is very rigid with huge durability helping it to stay in shape for longer without breaking. This is significant because it keeps the products in good condition for a long time. Second, it has a flexibility that enables it to twist and bend without breaking or snapping. Based on this versatility, it can be applied in so many different ways, which is helpful. Third, The nature of heat cure acrylic resin enable it to deal with is and every type of foul weather. So instead it stays in its shape and in its color regardless of the intense heat, intense cold, or even rain outside. This excellent properties makes acrylic acid resin an effective raw material in many of our daily products.

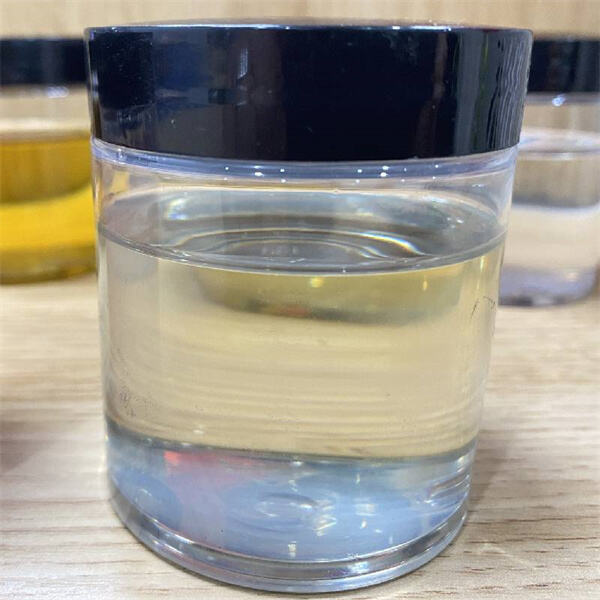

Fangxin utilizes acrylic resin molding for a variety of applications, one of which is coatings and adhesives. A coating is a special layer that is used to protect surfaces (floors, walls, etc.) against wear. They help protect the surfaces from looking good and protect them from scratches or wear. Adhesives are sticky substance that sticks things together. Acrylic acid resin can be used to produce tough, thin, and resilient films for coatings and adhesives. Acrylic acid resin adhesive is highly solvent-free heavy duty coating, and has great adhesive property, it easily bonds with various substratum including wood, metal and plastics. This is why they are suitable for various projects and repairs.

Acrylic acid resin is very suitable for the production of products requiring high strength of resistance weathering conditions. Acrylic acid resin that Fangxin produce is widely used to produce many kinds of heat cure acrylic products including but not limited to: car parts, toys, and outdoor furniture. These items should have the longevity that comes without damage or wear. Outdoor furnishings must to endure the sun, rain, wind, and so on, whilst toys ought to face up to getting jostled around with the aid of children. They too must flex, so they can ride along with movement, and accommodate temperature changes. Acrylic acid resin is suitable for the manufacture of these types of products, as it can meet all of these demands.

It is always advancing the field of polymer technology with new ideas, improvements, and excitement. Polymers are materials such as acrylic acid resin that can be molded into various shapes and used for a multitude of purposes. They are also constantly developing new sorts of polymers that could have better properties than an acrylic acid resin. Some new polymers, for instance, are even much finer quality than self curing acrylic resin in terms of strength and flexural resistance, and even climate resistance performance. This indicates that, the better technology gets, the more materials we have to draw from; the more exciting products we create that makes our daily lives easier.

For more than 30 years, we have been focused development, research, production sale of unsaturated resins, vinyl esters resins, alkyd acrylic resins, waterborne resins colored, color pastes and many other products, with the number products being close to 1000.Fangxin has been focused on research and development for more than 30 years, as well selling and production of unsaturated Acrylic acid resin, vinyl esters alkyd acetate resins color based on watercolors, color pastes, and other products. We stock more a thousand products.

The Company an experienced research and development staff and a state-of the-art R and D facility, to provide an all-in-one Acrylic acid resin for our customers, with a variety of customization options products. We also hold over 100 industry certifications as well as national certifications.Our team is comprised of highly skilled technical research and development group. Our team is equipped with the latest technology an R and D center. Fangxin has been able to obtain dozens of patents, 100 industry-specific certifications, and national certification awards. Additionally, we've participated in the creation of various industry standards for resin. We are confident in our ability offer one-stop customization and a one-stop shop for customers.

The company Acrylic acid resin in 1992 and has three production facilities of a large scale over 100 resin manufacturing lines, an annual production capacity of 800,000 tons and fixed assets worth more 800 million Yuan. Its total area of land covers 250,000 square meters.The company was founded in 1992, a registered capital of 350 million yuan as well as fixed assets that exceed 800 million yuan. The company covers an area 250,000 square meters and has three major production bases. The company also over 100 resin lines. In addition, its annual production capacity is 800,000 tones.

We're dedicated to Acrylic acid resin the quality quantity of resin products we offer in order to meet the different requirements of our customers and providing tailored solutions. Alongside other pertinent services, help our clients with consultancy on products including sample delivery, orders monitoring, product testing document for both maritime and land transportation.Our numerous satisfied customers include the following: Mexico, Kenya and Tanzania, United Arab Emirates, Russia and various other regions.We are dedicated to providing customers with custom solutions, while improving the quality of our resin products. We provide customers with consultation samples, delivery of samples, order tracking, testing of products, land and sea transportation document processing other related services. We have built long-term relationships with our customers across the world, including Russia, UAE, Kenya, Tanzania, Mexico and many more.

Copyright © Nantong Fangxin Chemical Co., Ltd. All Rights Reserved | Privacy Policy | Blog