This is especially true for the surface area that you need to paint the gel coat on – be sure to clean it first before you start spraying. Wash off surface with soap and water to remove dirt, grime, or grease. It provides better hooks for the gel coat to stick to it and provides you a better finish. The surface preparation of the area to receive the gel coat is very important; if the surface is not clean then the gel coat may not adhere properly and as a result the finished surface will be irregular. Take your time in this step, and ensure that it is nice and clean to proceed

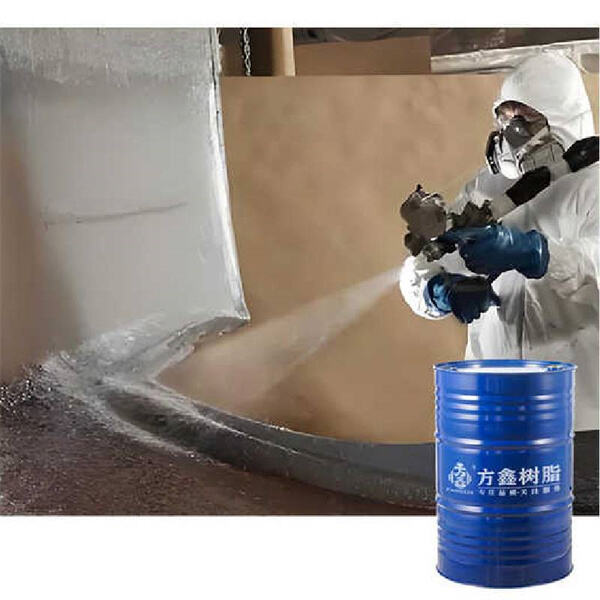

Working with any fiberglass gel coat requires safety. This is a Grid Resin type material that can cause harm if you get it on your skin or in your eyes. For your safety, spray only in protective equipment — gloves, goggles, mask etc. The equipment will protect you against harmful elements in the gel coat. Just remember, SAFETY FIRST in life and this should always be your motto, so never rush into your projects without all the PPE (personal protective equipment) needed!

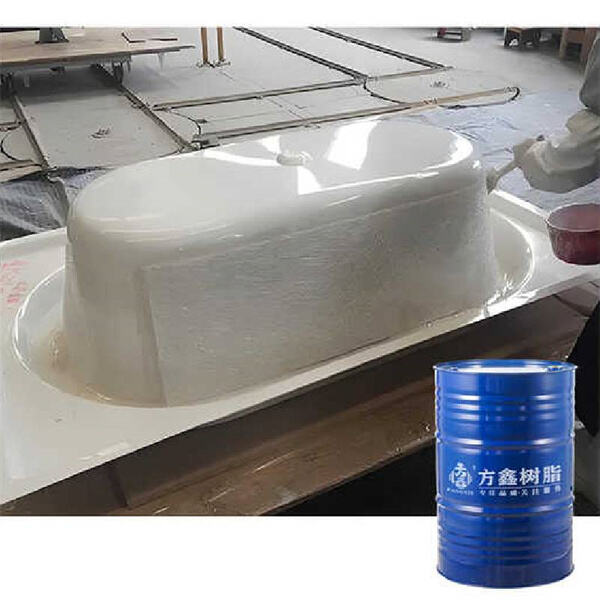

After getting your surf ex to go and putting on your form, it is time to combine your SMC Resin gel coat. Mix the gel coat according to package directions At times, you might require an additional chemical, known as a catalyst, to ensure proper curing of the gel coat. You want to make sure to mix this extremely well to eliminate any lumps that will destroy your finish. Having a properly mixed gel coat will guarantee that you receive an even smooth application

It is best to use a spray gun to apply gel coat. You need to be able to get even coverage over the surface, which is crucial for a good finish. Spray guns are available at all hardware shops or online. For you that use a spray gun, then just make sure you practice a bit before you work on your actual project. This will make you familiar with the tool and you will improve your brief a practice that remains.

Next, if you do not own a spray gun you can have to a brush or roller in applying the gel coat. This process can be slower, and an even finish can be more challenging to achieve. But it remains a decent choice, and you can also achieve decent results with a brush or roller. Simply be patient and gradually apply the gel coat as smoothly as possible.

A spray booth is something you may want to invest in if you are going to be working a lot with fiberglass. A spray booth is a dedicated area where paint and other coatings are sprayed. It keeps the spray contained allowing you to keep out of the path of something that could potentially be harmful. Spray Booth Investing in a spray booth is a good new spray painting tools in Australia if you are looking to make your work as easy as possible while also aiming to keep the area around you clean.

As with normal gel coat, the first step is preparation where you clean and sand the area being rug up. A good cleanup clears away any grime and allows the RTM Resin gel coat to adhere. This is where using sand paper is a good idea as it roughs the area up so that the epoxy can bond a lot better. These are extremely critical processes for an effective fixing.

Company is able, with Spraying fiberglass gelcoat research and development team as well as a state-of the-art R and D facility, to offer the complete solution to our customers, with a variety of customization options products. Additionally, we have over 100 industry certifications as well as national certifications.We have a skilled R and D department is highly Spraying fiberglass gelcoat and technical. Our team has a modern R and D center. Fangxin has already earned dozens of patents, over 100 industry-specific certifications, national awards for certification. We have also participated in the formulation of various resin industry standards. We are confident in our ability to offer the ultimate customization, and single shop for customers.

Our focus is on improving the quality and quantity our resin products, meeting the varied needs of our clients, and offering tailored solutions. In addition to the other services, we assist our customers with consulting on product samples, delivery samples, order monitoring, product testing and document application for both shipping by sea and land.Our numerous satisfied customers include our clients from Mexico, Kenya and Tanzania, United Arab Emirates, Russia and many more regions.We are committed to improving quality and variety of resin products that meet Spraying fiberglass gelcoat requirements of customers and providing them with custom solutions. We offer customers assistance with product consultation as well as sample delivery, purchase tracking, product testing as well as land sea transport document processing, and other services. We have established long-term collaboration with our clients across the world, specifically Russia, UAE, Kenya, Tanzania, Mexico and many more.

The company was founded in 1992. It home to three production facilities of a large Spraying fiberglass gelcoat and more 100 resin production lines, a total annual production capacity of 800,000, and fixed assets worth more than 800 million Yuan. The total land area covers 250,000 square meters.In the year 1992, the company founded with a capital of 350,000,000 yuan. Its fixed assets amounted to more than 800,000,000 yuan. The company covers 250,000 square meters, and it has three large production bases. The company also over 100 resin lines. And its annual capacity of production is 800,000 tones.

For more than 30 years, we've been focusing on research, development, production and sales unsaturated and uncolored resins, vinyl ester resins, alkyd and acrylic resins, waterborne resins, colored, color pastes other products, with almost 1,000.Fangxin been focused on research and development for over 30 years, as well as production and sales, of unsaturated epoxies esters alkyd acetate resins water-based resins, color Spraying fiberglass gelcoat as well as color pastes and other products. We have more a thousand products.

Copyright © Nantong Fangxin Chemical Co., Ltd. All Rights Reserved | Privacy Policy | Blog