Resin is a unique substance that can be molded into various shapes like plastic, fine jewelery or even boats! Get ready to be introduced into the world of vacuum infusion resin today. This particular resin has been of massive help in the manufacturing of composite materials where separate yet distinct material are combined to create a superior and more resilient whole.

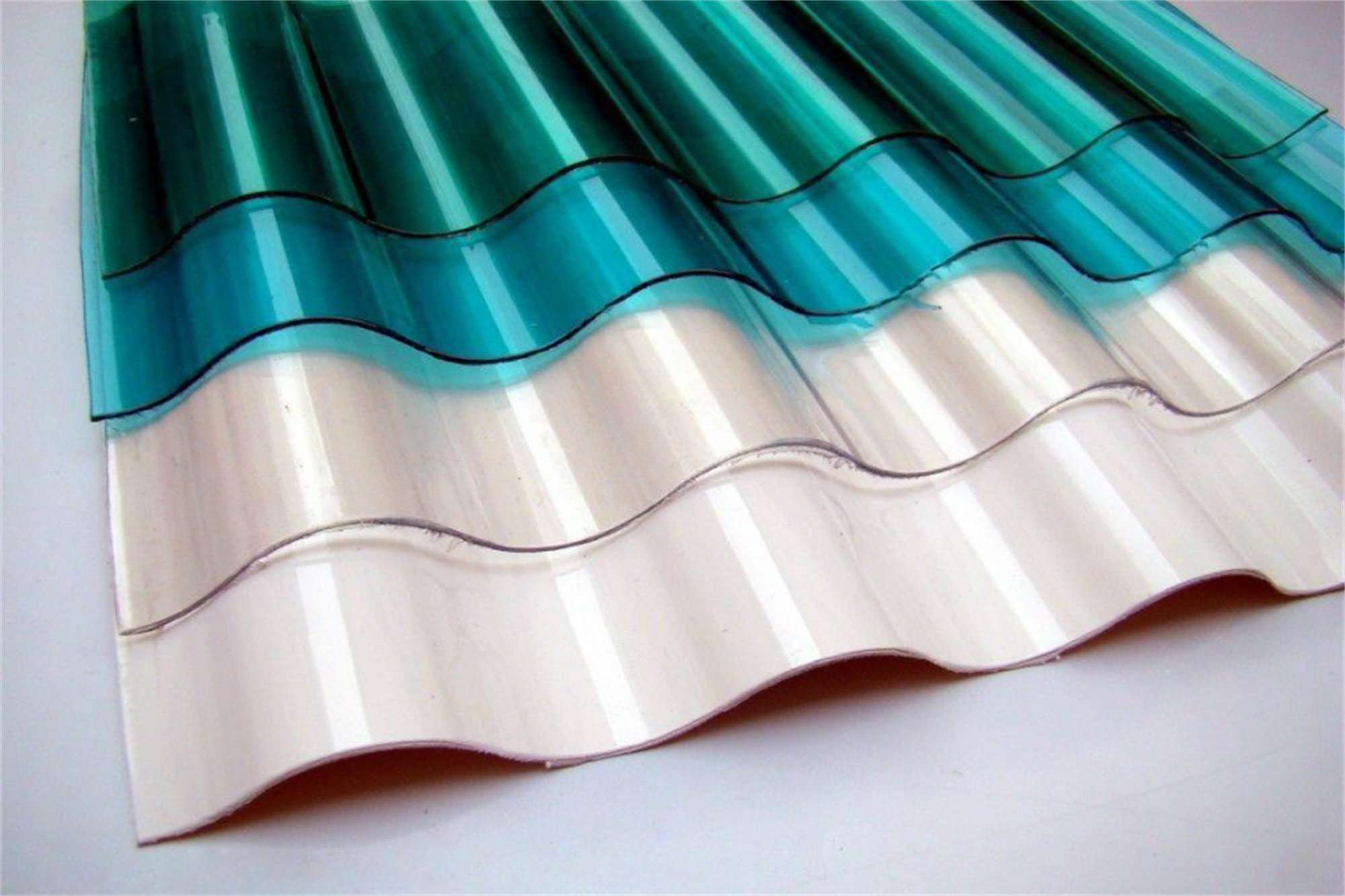

Another thing that is interesting about composites - you know, there are almost like God created it with things and said lets stick some of this here.) Resin Infusion using Vacuum is very popular method of developing composite materials. This mixture is a blending of the resin with other ingredients. The mixture is then vacuumed into a mold. The vacuum has no relevance, but it serves the principle purpose to make this mixture settle evenly through out the moldThis ensures that everything will be covered equally. Adding Raisins to help Avoid Bubbles - If too many bubbles get into the final loaf during baking, it will weaken the bread. If done successfully, the output will be a very strong composite that can then go into fabricate everything from airplane wings to sunglasses.

Vacuum Infusion Of Composite Materials Resin - Top Benefits For starters, it binds the materials together with very tight bonds. As we know the material is composite made so if this special resin will be used in making its tough and not easy to break, it's very important for many products. Also the proper spread of all the materials are fully controlled by vacuum infusion process. This braininess also stops any weak points from showing up in the composite material; which helps make it stronger and more resilient.

Careful Mixing of Resin with other Components When Working With Kathy Dry-Ply (for vacuum infusion!) Doing this properly from the outset ensures the final product will be of high quality and performs well. More over, the vacuum ued for this process must be of background to remove air from mold. This is vital as it ensures no bubbles form that might undermine the composite and make it weak. By doing all these you can obtain great results with resin for infusion under vacuum.

The marine industry is the foremost example of why a resin for vacuum infusion would be useful. Boats have to be strong Boats need to be very sturdy and super tough because they are going up against mothernature on sea that is likely full of sharp rocks, sudden turns or deep drops. Resin out of the stable for vacuum infusion, manufacturers can manufacture composite materials that are both incredibly light and strong. This is a huge plus that it enables boats to be built even stronger without adding more weight. The lighter the boat, the faster and more efficient they move through water, a critical component for high performance.

Finally, vacuum infusion resin can provide a better efficiency and long term stability for various industries. The delivers savings to enable the company builders less energy, raw material and yet more robust products that are durable. The vacuum infusion process can also increase the speed of production, because it allows for rapid and even distribution of mixture into the mold. Companies can save manufacturing time and costs due to this efficiency which eventually makes the process smoother.

We're dedicated to improving the quality range of resin products we offer to meet the varied requirements of our customers and offering bespoke solutions. We offer a variety services to our customers, such as product consultation including sample delivery monitoring, testing of products and documentation for both sea and land shipping.Many of our satisfied customers are Mexico, Kenya, Tanzania among others. We also customers in the United Arab Emirates, Russia as well as other regions.We're committed to providing our customers with custom Resin for Vacuum Infusion, while improving quality of our resin products. We provide our customers with services like product consultation and delivery products, monitoring orders, testing of products as well as document processing for shipping by ocean and land and many more. We have developed long-term relationships with customers across the world which includes Russia, UAE Kenya, Tanzania Mexico and many more.

With a highly experienced R and D team, state of the art R and D center, a number of patents, more than 100 industry certifications, national certifications, and an active part in the development of a variety of resin industry standards, the company is able to provide our customers one-stop, and product customization services.We have a qualified technical R and D team. Our team Resin for Vacuum Infusion with the latest technology in an R and D center. Fangxin has achieved dozens of patents, over 100 industry certifications, as well national certification awards. We have also been involved in the development of a variety of resin industry standards. We are very confident that we can offer customers one-stop and customization services.

The company Resin for Vacuum Infusion in 1992 and has three production facilities of a large scale over 100 resin manufacturing lines, an annual production capacity of 800,000 tons and fixed assets worth more 800 million Yuan. Its total area of land covers 250,000 square meters.The company was founded in 1992, a registered capital of 350 million yuan as well as fixed assets that exceed 800 million yuan. The company covers an area 250,000 square meters and has three major production bases. The company also over 100 resin lines. In addition, its annual production capacity is 800,000 tones.

We have been focusing the development, research production unsaturated epoxies vinyl ester resins over 30 years.Fangxin has been involved in the research and development of over 30 years, as well as production and sales, of Resin for Vacuum Infusion epoxies and vinyl esters alkyd acetate resins color made of watercolors, color pastes, and many other products. We offer more than 1,000 products.

Copyright © Nantong Fangxin Chemical Co., Ltd. All Rights Reserved | Privacy Policy | Blog