What do you think toys, car parts, and boats are made of? These are made of Polyester unsaturated resin —they are very important raw material. Some resin can still stick, because it is a special resin. “Unsaturated” refers to the fact that this resin has not yet activated all of its potential bonding sites with other materials.

Unsaturated polymer resins consist of small aggregates known as monomers. A polymer is a long chain of repeating units called monomers. Like connecting lots of little pieces to make a long, sturdy rope. Carbon and hydrogen are the constituent monomers in unsaturated polymer resins. These atoms are the building blocks of many different materials in the world around us.

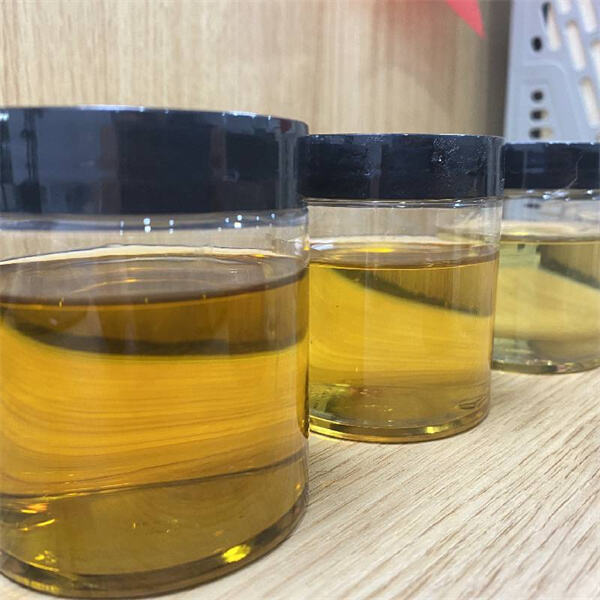

In the course of making the resin, the monomers are combined with other chemical compounds called initiators and accelerators. These chemicals initiate the process that allows for the bonding of the monomers. The mixture is then heated or exposed to a specific light after mixing. This is an important step, as it allows the monomers to attach closely to one another, creating a solid, tough resin. That solid resin is then used to make a variety of products.

In this article, we will describe the many benefits of using Unsaturated polyester resins that contribute to its popularity among manufacturers. The main reason is that they can be molded into any shape. This flexibility does allow manufacturers to design very cool detailed products. In turn, that material can create some cool and colors and shapes to make a toy interesting. They can even be dyed to suit the colour of your choice so, they are compatible with various products.

The other good thing about unsaturated polymer resins is their strength and durability. They are resistant to heat, chemicals and impact meaning they can be used for a long time without breaking down. They are commonly used for the construction of things like pipes, roofs, and flooring, for instance. They are also used in making many important parts in cars, including bumpers and hoods that must withstand a lot of force and pressure.

In the past several years, there have been many exciting new changes in the production of unsaturated polyester resins. However, one of the most notable developments is the use of low-temperature curing resins. These special resins can cure, or set, at lower temperatures, for example 110 degrees Celsius. That's kind of cool because it saves energy and increases product turnaround process.

Furthermore, there is progress in additives that can enhance unsaturated polyester resins. Additives are added to enhance the properties of a material. Some additives, for example, can strengthen the resin or help the resin have damage resistance to some of the light. A second major change is using renewable materials, such as plant-based monomers, to produce these resins. (That is good for the environment, because it takes less of those non-renewable resources.)

Our focus is on improving the quality and quantity our resin products, meeting the varied needs of our clients, and offering tailored solutions. In addition to the other services, we assist our customers with consulting on product samples, delivery samples, order monitoring, product testing and document application for both shipping by sea and land.Our numerous satisfied customers include our clients from Mexico, Kenya and Tanzania, United Arab Emirates, Russia and many more regions.We are committed to improving quality and variety of resin products that meet unsaturated polymer resin requirements of customers and providing them with custom solutions. We offer customers assistance with product consultation as well as sample delivery, purchase tracking, product testing as well as land sea transport document processing, and other services. We have established long-term collaboration with our clients across the world, specifically Russia, UAE, Kenya, Tanzania, Mexico and many more.

The company founded in 1992. It has three production facilities of a large scale that include over 100 resin manufacturing lines, an annual production capacity of 800,000 tons and fixed assets are worth more than 800 million Yuan. The total area covers 250,000 square meters.The company was established 1992 and has an initial capitalization of 350 million yuan, and fixed assets of more 800 million yuan. The company covers an area 250,000 square meters, and it has three huge production bases. It also more than 100 resin lines. The annual unsaturated polymer resin capacity is around 800,000 tones.

We have been focusing the development, research production unsaturated epoxies vinyl ester resins over 30 years.Fangxin has been involved in the research and development of over 30 years, as well as production and sales, of unsaturated polymer resin epoxies and vinyl esters alkyd acetate resins color made of watercolors, color pastes, and many other products. We offer more than 1,000 products.

Company is able, with unsaturated polymer resin research and development team as well as a state-of the-art R and D facility, to offer the complete solution to our customers, with a variety of customization options products. Additionally, we have over 100 industry certifications as well as national certifications.We have a skilled R and D department is highly unsaturated polymer resin and technical. Our team has a modern R and D center. Fangxin has already earned dozens of patents, over 100 industry-specific certifications, national awards for certification. We have also participated in the formulation of various resin industry standards. We are confident in our ability to offer the ultimate customization, and single shop for customers.

Copyright © Nantong Fangxin Chemical Co., Ltd. All Rights Reserved | Privacy Policy | Blog