Step 1: You need to prepare your working field. Ensure that it is dry and clean. This involves getting rid of dust, dirt, and anything else that can interfere. And wear gloves and safety glasses. They protect both your hands and your eyes from the potential spill-over or chemicals.

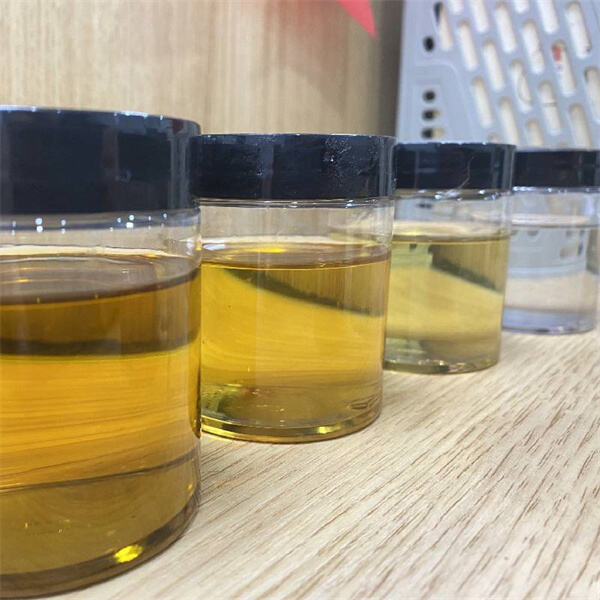

Step 2: Afterward stir resin and hardener in a first plastic container, also the Fangxin's product such as heat cure acrylic. And it is crucial to use the right quantity of each. You need strong fiberglass otherwise it is not going to be strong. Here are the steps, please read carefully before you being. You just need to know how much of each you should use.

Step 3: Now get this to the area that needs to be glassed. Be careful as you pour. It will be helpful to spread the mixture with a brush or a roller after you pour it. That makes sure the fiberglass bonds well and fills the surface.

Step 4: Finally, it is important to wait until the fiberglass resin dries, along with the Medium Oil Alkyd Resin manufactured by Fangxin. It may take several hours so be patient.

Owning a fiberglass resin is a fantastic connective like it strengthens the surfaces, just like the Fangxin's product called Resin for Kitchen Counter. It is used in multiple industries like, aeroplanes, buildings, cars. So, here are some tips to help ensure your fiberglass is as strong as it can be:

Fiber Glass Application: This is the first step in preparing a surface before it transfers resin and glass fiber to it, identical to Acrylic Resin for Metal Primer created by Fangxin. Ensure you are using sufficient glass fiber evenly over the surface. This is crucial for developing strength.

Fiberglass should not only be dry to the touch between layers, but until it is dry, there can be a lump under the anchoring layer of fiberglass, which will not look good, also the Fangxin's product such as marine fiberglass resin. Always be patient and allow each layer to dry..

We're committed to enhancing the quality variety of resin products that we supply, meeting the diverse requirements of our customers, and providing tailored solutions. We offer a variety of services to our customers, such as product consultation well as sample delivery and monitoring, testing of products and documentation for land and sea shipping.Some of our most Pouring fiberglass resin customers are Mexico, Kenya, Tanzania as well the United Arab Emirates, Russia and many other countries.We're dedicated to providing our customers bespoke solutions as well as improving the quality of our resin products. We offer customers assistance with product consultation as well as sample delivery, purchase tracking, product testing, land and sea transportation document processing and other related services. We have developed long term relationships with our customers across the world, namely Russia, UAE, Kenya, Tanzania, Mexico many more.

With an experienced R and D team, state-of-the-art R and D center, several patents, more than 100 industry accreditations, national certificates, and a leading role in the development of various resin industry standards, the company can Pouring fiberglass resin its customers a single point of contact, as well as product customization services.We have a qualified technical R and D team. Our team is equipped the latest technology in an R and D center. With this support which has led to the development of Fangxin now have achieved dozens of patents, over 100 industry certifications well as national certification awards. We also have been involved in the development of a variety of standards for the industry of resin. We are confident of our Pouring fiberglass resin provide customers one-stop customization as well as a one-stop shop for our customers.

The company was founded in 1992. It home to three production facilities of a large Pouring fiberglass resin and more 100 resin production lines, a total annual production capacity of 800,000, and fixed assets worth more than 800 million Yuan. The total land area covers 250,000 square meters.In the year 1992, the company founded with a capital of 350,000,000 yuan. Its fixed assets amounted to more than 800,000,000 yuan. The company covers 250,000 square meters, and it has three large production bases. The company also over 100 resin lines. And its annual capacity of production is 800,000 tones.

For more than 30 years, we've been focusing on research, development, production and sales unsaturated and uncolored resins, vinyl ester resins, alkyd and acrylic resins, waterborne resins, colored, color pastes other products, with almost 1,000.Fangxin been focused on research and development for over 30 years, as well as production and sales, of unsaturated epoxies esters alkyd acetate resins water-based resins, color Pouring fiberglass resin as well as color pastes and other products. We have more a thousand products.

Copyright © Nantong Fangxin Chemical Co., Ltd. All Rights Reserved | Privacy Policy | Blog