These two materials complement each other so well to make strong and durable products for a wide variety of projects. Here, we are going to discuss about Fangxin fiberglass resin and hardener, what they do and how they can help you with your fun projects using fiber.

Epoxy resin and hardener are special materials used in epoxy composites (or just composites), which turn into solid and hard products. These react to each other and form a chemical reaction, to transform the mixture into something hard. We use fiberglass resin which is a high-end product that creates a very strong bond. Strong bond is also very essential as it can withhold science and pressure without falling apart. Fangxin fiberglass resin and hardener have diverse applications. This Fiberglass resin is an excellent combination if you would like to fix a boat, fill cracks in walls, or make unique pieces of art.

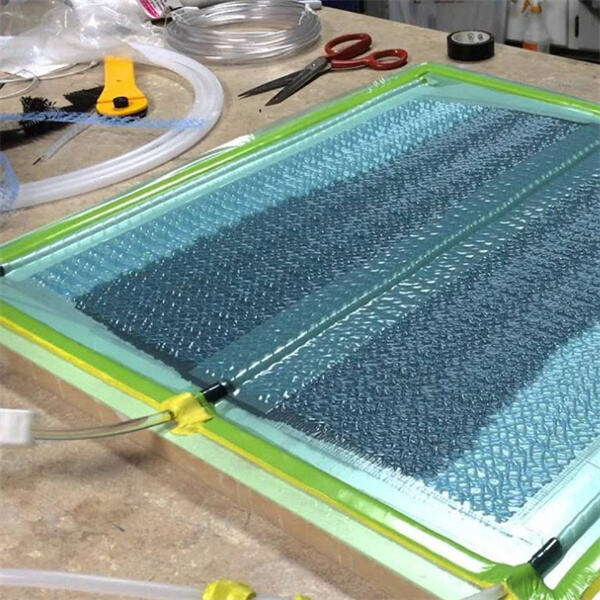

However, one of the keys steps in using Fangxin fiberglass resin and hardener is mixing them properly. More so, they cannot be utilized by themselves as the hardener will activate the resin causing it to cure. You mix them correctly by following the instructions written on its package, attentively. Getting the Fiberglass resin tape mixing ratio right is very important. Without the right combination during mixing, the outcome may be a brittle and unstable material. Duh, mixing is a big part in ensuring that your project actually sounds good and is successful.

Fiberglass resin and hardener is very commonly used for boat repair. We've all heard the horror stories of boats constantly in the path of heavy winds and rain over time. For this reason, materials should be used that can be beneficial in protecting the boat. The rolling fiberglass resin boats are made with a strong fiberglass material which allows them to be more resistant to harsh conditions for an extended period of time. Fiberglass resin and hardener for filling pits on the boat hulls or strengthening weak areas. Selecting the correct fiberglass resin and hardener ratio for your specific boat repair project is really the key.

If you are using Fiberglass resin with resin and hardener, there may be some problems. A frequent problem is air bubbles within the mixture. While these bubbles can a lot of times weaken the material. The two components must be mixed very carefully as air bubbles will come to remain and also the mixture should be layered in thin layers. This fire resistant fiberglass resin will help to keep the mixture in a still viscous state and to avoid any separation. Improper curing is another issue that can happen. This indicates the resin and hardener did not mix properly due to excess or insufficient hardener being used. To prevent this problem, ensure that you follow the instructions on your package correctly as well as use the proper ratio.

With a highly experienced R and D team, state of the art R and D center, a number of patents, more than 100 industry certifications, national certifications, and an active part in the development of a variety of resin industry standards, the company is able to provide our customers one-stop, and product customization services.We have a qualified technical R and D team. Our team Fiberglass resin and hardener with the latest technology in an R and D center. Fangxin has achieved dozens of patents, over 100 industry certifications, as well national certification awards. We have also been involved in the development of a variety of resin industry standards. We are very confident that we can offer customers one-stop and customization services.

For over thirty years, we have been focusing on development, research, manufacturing and sale unsaturated resins and vinyl ester resins, alkyd resins, acrylic resins, waterborne resins, colored color pastes, and other products, having a product number nearly 1000.Fangxin has been focused on the research development of over 30 years, as well the production sale of unsaturated epoxies, vinyl esters alkyd acetate resins Fiberglass resin and hardener colors, color pastes, and other products. We have over 1,000 products.

We're dedicated to Fiberglass resin and hardener the quality quantity of resin products we offer in order to meet the different requirements of our customers and providing tailored solutions. Alongside other pertinent services, help our clients with consultancy on products including sample delivery, orders monitoring, product testing document for both maritime and land transportation.Our numerous satisfied customers include the following: Mexico, Kenya and Tanzania, United Arab Emirates, Russia and various other regions.We are dedicated to providing customers with custom solutions, while improving the quality of our resin products. We provide customers with consultation samples, delivery of samples, order tracking, testing of products, land and sea transportation document processing other related services. We have built long-term relationships with our customers across the world, including Russia, UAE, Kenya, Tanzania, Mexico and many more.

The company Fiberglass resin and hardener in 1992 and has three production facilities of a large scale over 100 resin manufacturing lines, an annual production capacity of 800,000 tons and fixed assets worth more 800 million Yuan. Its total area of land covers 250,000 square meters.The company was founded in 1992, a registered capital of 350 million yuan as well as fixed assets that exceed 800 million yuan. The company covers an area 250,000 square meters and has three major production bases. The company also over 100 resin lines. In addition, its annual production capacity is 800,000 tones.

Copyright © Nantong Fangxin Chemical Co., Ltd. All Rights Reserved | Privacy Policy | Blog